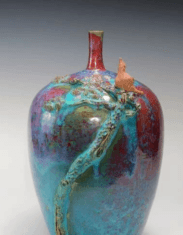

A beam of sunlight penetrates the dust of a thousand years, illuminating the glaze flow of ice crackles – this is the first impression left by the Song dynasty official kilns porcelain to the world. Among the five famous kilns of Song porcelain, the official kiln has become a treasured heirloom sought after by collectors through the ages for its unique identity of “purple mouth and iron foot”. What kind of craftsmanship code is hidden behind this artistic feature that combines the best of nature with the best of art? Behind it reflects what the Song Dynasty aesthetic pursuit?

I. Purple mouth and iron feet: the DNA of the official kiln logo

As an exclusive mark of the imperial kilns of the Song Dynasty, “purple mouth and iron foot” refers to the contrast between the lavender tone of the mouth and the deep brown color of the footrim. This seemingly natural color difference is actually the result of multiple processes precisely controlled:

Iron oxide is precipitated from the clay, which contains 3%-5% iron, in the firing at 1280°C.

The mouth rim is formed by the glaze flowing “off”, and the carcass is oxidized for a second time to show a purple color.

The unglazed part of the footrim is in direct contact with the kiln atmosphere, and the iron element is oxidized to form an iron-brown color.

Archaeological tests have shown that the carcass iron content of the fragments of the government kilns under the Suburbs in the Southern Song Dynasty is as high as 4.7%, which is far higher than that of the civilian kilns of the same period, which is 1.5%-2%. This “no expense spared” choice of materials, confirming the “Tan Zhai Pen Heng” contained in the “inheritance of the former capital system, set up kilns in the Xunai Division” of the royal spirit.

Second, process decoding: the perfect balance of natural and artificial

The birth of the Purple Mouth and Iron Feet is proof that the Song craftsmen reached the peak of kiln variation control. Through three layers of progressive technological innovation, a wonderful dialogue between glaze and tire bone was realized:

Glaze formula revolution Adopting lime-alkali glaze to replace the traditional lime glaze, reducing the calcium oxide content from 15% to 8%, while boosting the potassium and sodium content to 6%. This change allows the glaze to flow slowly at high temperatures, resulting in the phenomenon of “the glaze not reaching the bottom”.

Nail Firing Technique Sesame nails, made of special refractory clay, are used to overhang the object and fire it. This not only ensures that the feet are fully exposed to the kiln atmosphere, but also avoids contamination of the sagger. The pegs excavated from the Tiger Cave kiln site in Hangzhou are only 2-3 millimeters in diameter, demonstrating an astonishing degree of refinement.

Reduction-Oxidation Two-Stage Firing A sudden injection of air at the end of the firing process changes the kiln from a reducing atmosphere to an oxidizing state. This critical turning point prompts a secondary oxidation reaction of the iron elements in the carcass, culminating in a gradual color spectrum from purple-brown to iron-brown.

Aesthetic code: the physical expression of the spirit of Song literati

Zikou Iron Foot is not only the crystallization of technology, but also the physical presentation of the aesthetics of “Taoism and Nature” in the Song Dynasty. Its aesthetic value is reflected in three dimensions:

The philosophical interpretation of the beauty of mutilation The “purple mouth” of the mouth and the “iron foot” of the footrim break the sense of completeness of the glazed porcelain. This kind of “intentional defects” is in line with Su Shi’s aesthetic interest of the literati, “the moon has its own shade and roundness”, and injects spiritual vitality into the regularity.

Visual Tension of Color Contrast The subtle contrast between the warmth of mauve and the hardness of iron-brown is similar to the “five colors of ink” in ink painting. The transition of the glaze color of the Official Kiln String Bottle in the Palace Collection perfectly illustrates the “Essentials of Ge Gu” standard of evaluation, which states that “pinkish green is the most important color, followed by pale white”.

The return to the true pursuit of materiality, the contrast in texture between the bones and the thick glaze, highlights the concept of “great ingenuity is like clumsiness” in the creation of objects. Just as Zhu Xi said, “to achieve knowledge through materiality”, the craftsmen of the kilns pay tribute to the laws of nature by showing the essence of the materials.

Echoes of a Thousand Years: A Legend Validated by Modern Technology

With the help of X-ray fluorescence spectrometry, scientists have unveiled the mystery of the color of the purple mouth and iron feet: the Fe₂O₃ content detected in the purple domain is as high as 7.2%, while the iron foot part reaches 9.5%. This difference stems from the gradient change of oxygen concentration during firing – the oxygen content at the mouth rim is 8-10%, while the area of the mat cake where the rim touches the foot is as high as 15%.

A 2018 restoration experiment at the Southern Song Official Kiln Museum in Hangzhou confirmed that when the kiln temperature was raised to 1,260°C, the air intake was suddenly increased by 30% for 20 minutes and then rapidly cooled down, successfully reproducing the typical characteristics of heirloom official kilns. This data provides a scientific standard for dating the “Purple-mouthed and Iron-footed Official Kilns”.

From the celadon tripod furnace in the Tokyo National Museum to the sunflower petal mouth wash in the British Museum, those zigzou iron-footed official kilns spanning over a thousand years are still telling the world about a dynasty’s pursuit of excellence. When our fingertips touch these warm glazes, what we touch is not only the craftsmanship of the Song people, but also the spiritual height of an era.